Stamping sustinably.

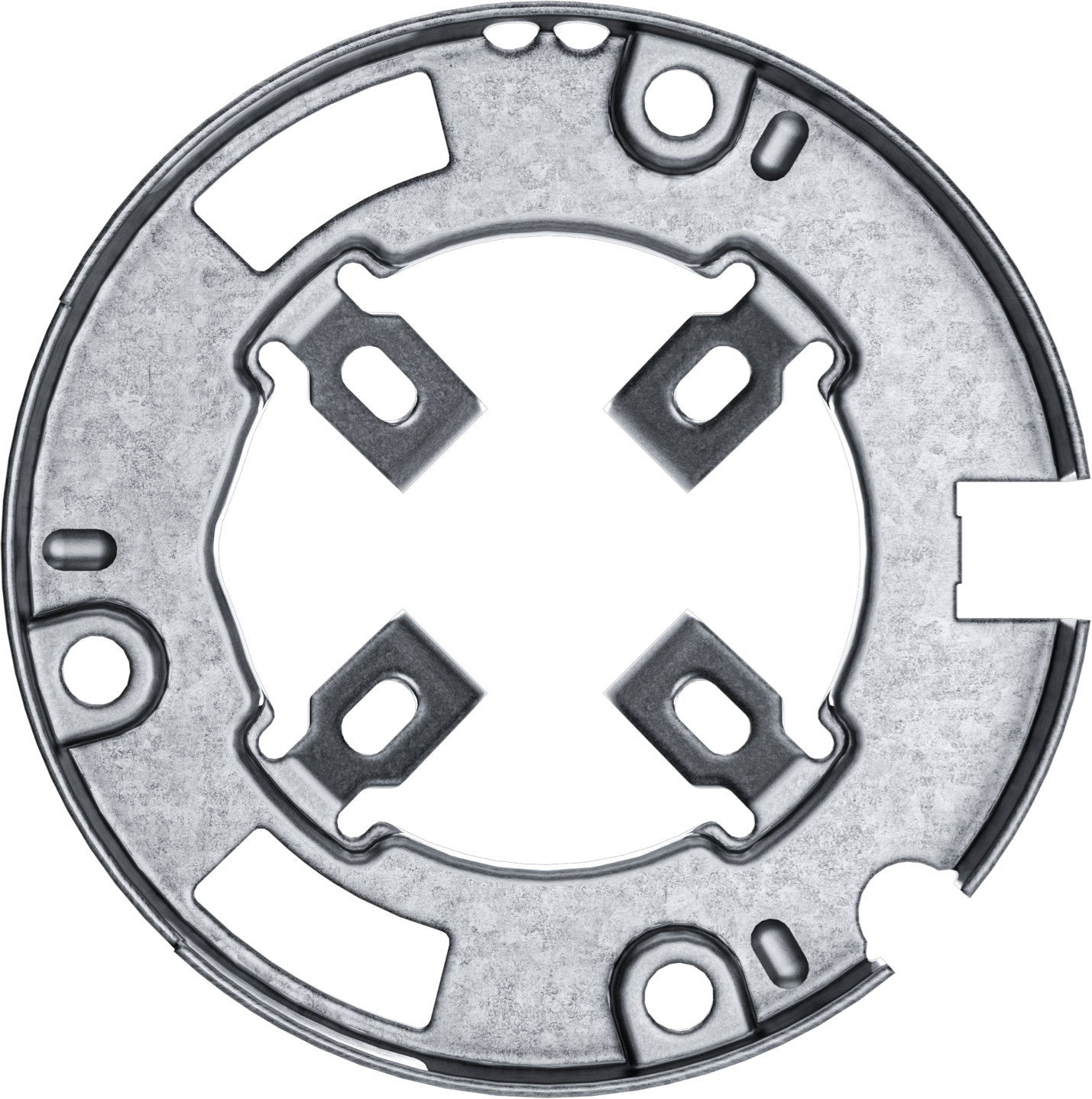

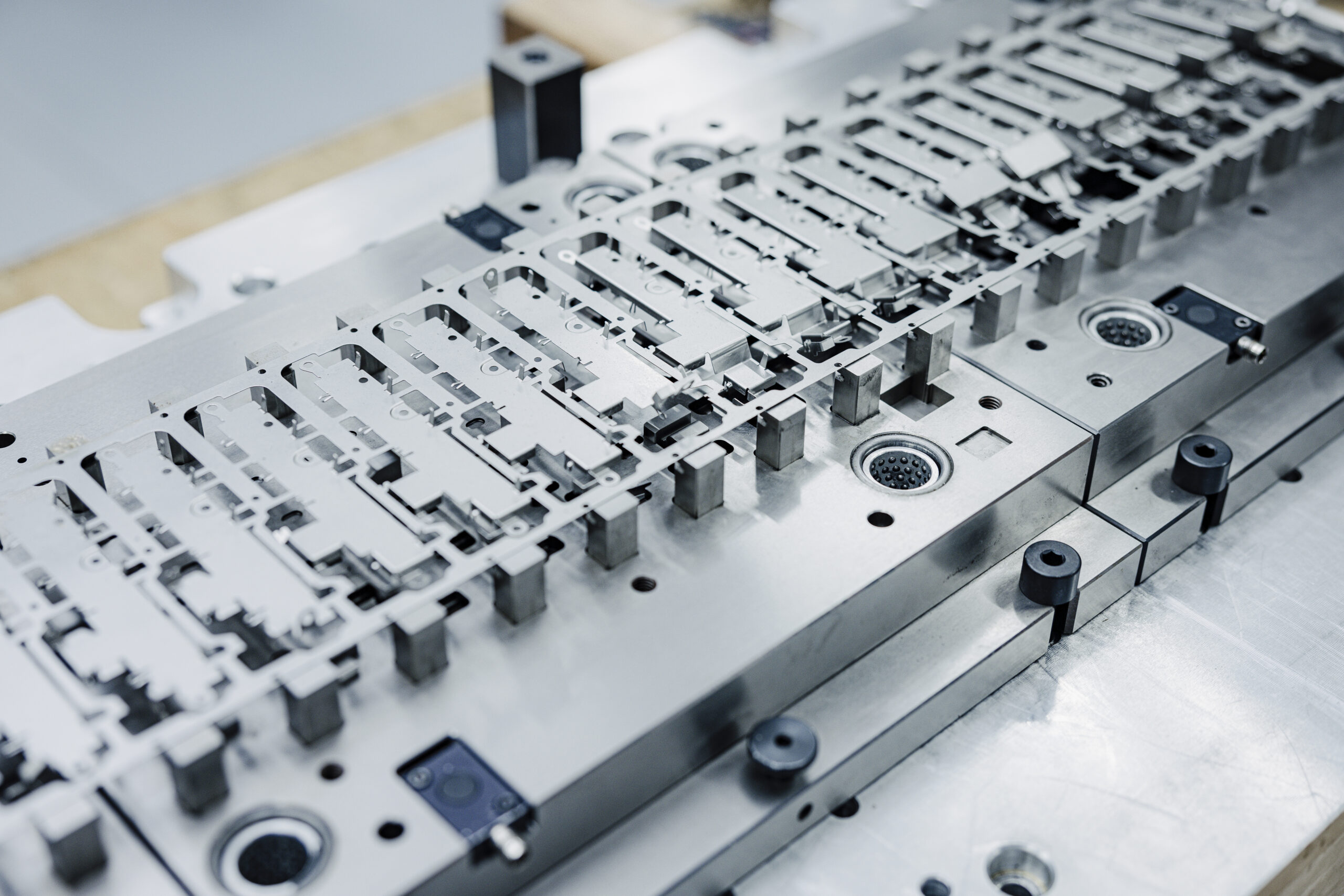

Using an impressive array of machinery, consisting of over 50 punching and bending machines (multi slides), primarily Bihler, and more than 30 stamping machines like Bruderer and Kaiser, with press forces of up to 160 tons and table lengths of up to 160 cm, the SPRINGTEC Group manufactures punching and bending parts with the highest precision. Our stamping facilities are equipped with a modern tooling workshop and supported by forward-thinking tool designers. We create and maintain a close and reliable relationship with our customers right from the start, to offer them not only customized products but also tailor-made logistics and packaging solutions. In addition to our high quality standards, sustainability is a central focus in all of our processes. We are now focusing on eco-friendly approaches and practices to make our manufacturing business greener and more future-proof.

We gladly pay the price for green energ.

Since 2022, the SPRINGTEC Group has been taking significant steps towards decarbonization and carbon neutrality. Through the purchase of green energy sourced from wind power and other renewable sources, we commit to minimizing our ecological footprint and actively contributing to environmental conservation. These are significant measures in the right direction, for which we pay the price with full conviction.

Green Future? Full stem ahead.

The purchase of green energy is naturally just one aspect for our SPRINGTEC Group. We are fully committed to sustainable and environmentally friendly practices. Accordingly, we invest in our own power generation by photovoltaic systems, implement targeted measures to reduce our energy consumption, hold our suppliers accountable, regularly assess our concepts, and collaborate with environmentally conscious companies like EcoVadis—with full force into a green future.

2023

First SPRINGTEC plant produces CO2-neutral

2024

Further SPRINGTEC plants produce CO2-neutral

2025

All SPRINGTEC plants produce CO2-neutral

by 2030

Decarbonization of supply chains especially metal suppliers

Environ-mental awareness? Already shaping us today.

Within our six sister companies, we have already implemented comprehensive measures to enhance energy conservation and efficiency. In production, we use energy-efficient LED lighting and environmentally friendly heating systems like geothermal energy. Furthermore, we are actively working to equip all SPRINGTEC Group locations with photovoltaic systems to produce our own electricity and feed excess power into the grid in the future. Furthermore, these initiatives and goals do not only pertain to our own activities but also extend to those of our suppliers. By no later than 2030, five years after our corporate group, we aim to make our entire supply chain carbon-neutral as well.

For a top-performing cmpany.

Since 2025, all SPRINGTEC plants have been producing entirely carbon-neutral. Every day we strive to keep our ecological footprint as small as possible. However, our sustainability goals do not stop there - on the contrary, sustainability is also a main topic in our workforce planning. We can achieve an above-average apprenticeship rate, allowing us to drive our growth with self-trained specialists. This success is already reflected in an exceptionally young, forward-thinking team. A new generation of stamping and bending experts who will continue forging the SPRINGTEC Group into what it already is today: Sustampable.